High Frequency PCBs

High Frequency (HF) PCB is used to transmit electromagnetic waves in the frequency of GHz with minimal losses in a variety of applications, including mobile, microwave, radio frequency (RF), and high-speed design applications. Hence, printed circuit boards with some specific characteristics are used to transmit these electromagnetic waves.

What is High Frequency (HF) PCB?

The features of high frequency PCB

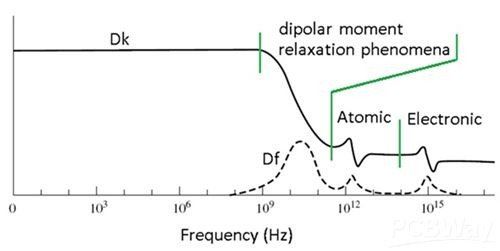

DK should be small and stable enough, usually the smaller the better, high DK may lead to signal transmission delay.

DF should be small, which mainly affect the quality of signal transmission, the smaller DF could make smaller signal wastage accordingly.

The thermal expansivity should be the same with copper foil as much as possible because the difference will lead to copper foil separated in the changes of cold and heat.

Water absorptivity must be low, high water absorptivity will affect DK and DF when in a wet environment.

Heat-resisting property, chemistry resisting, impact endurance, peel off resisting must be good.

Materials used for HF circuit board.

High frequency board for wireless applications and data rates in the upper GHz range have special demands on the material used:

Adapted permittivity.

Low attenuation for efficient signal transmission.

Homogeneous construction with low tolerances in insulation thickness and dielectric constant.

Generally speaking...

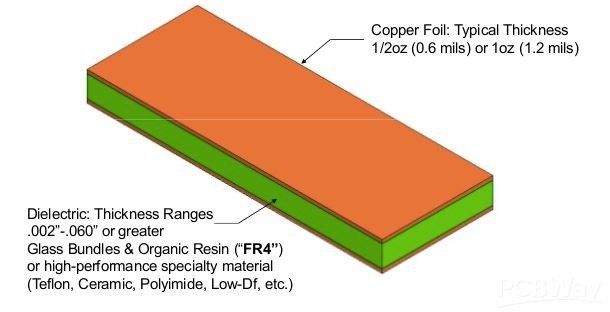

High frequency can be defined as frequency above 1GHz. Currently, PTFE material is widely used in high frequency PCB manufacturing, it's also called Teflon, which frequency is normally above 5GHz. Besides, FR4 or PPO substrate can be used to the product frequency among 1GHz~10GHz. These three high frequency substrates have below differences:

Concerning the laminate cost of FR4, PPO and Teflon, FR4 is the cheapest one, while Teflon is the most expensive one. In terms of DK, DF, water absorption and frequency feature, Teflon is the best. When product applications require frequency above 10GHz, only can we choose Teflon PCB substrate to manufacture.

The performance of Teflon is far better than other substrates, However, the Teflon substrate has the disadvantage of high cost and large heat-resisting property. To improve PTFE stiffness and heat-resisting property function, a large number of SiO2 or fiber glass as the filling material.

On the other hand, due to molecule inertia of PTFE material, which it is not easy to combine with copper foil, thus, it needs to do the special surface treatment on the combination side.

Check AlteraFlex High Frequency PCB manufacturing capabilities in the following table:

| Feature | Capability |

|---|---|

| Material | RO4003C, RO4350B, Ro3003, Ro3010, RT5880 |

| Min. Track/Spacing | 2mil |

| Min. Hole Size | 0.15mm |

| Finished Cooper | 1-2oz |

| Board Thickness | 0.2-3.2mm |

| Surface Finishing | Immersion gold, OSP, Hard Gold,Immersion SIlver,Enepig |

| Finsih Cooper | 0.5-13oz |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green |

| Silkscreen | White, Black |

| Via Process | Tenting Vias,Plugged Vias,Vias not covered |

| Testing | Fly Probe Testing (Free) and A.O.I. testing |

| Build time | 7-10 days |

Have Questions?

If you have any questions or need any further information, please feel free to contact your dedicated customer service.