CALL NOW!

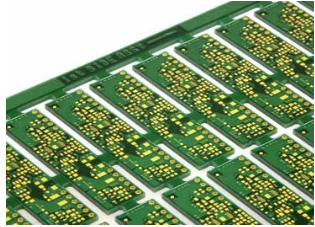

PCB Panel Creation

PCB panel is a consideration for both PCB manufacturing and PCB assembly cause some boards are irregular. The panel can reduce the time and labor for production and testing.

What is the panel?

That means we help you connect the single boards(same or different are both OK) on one big panel by different route process, then it will be easy for you to break them into single PCB.

For the routing process, it has three types: V-scoring, Tab route, and stamp holes

PCB Capabilities

1. V-scoring

Panel with V-Cut/V-Scoring/V-Groove

For V-scoring panelization, space between boards can be 0mm or 3mm. Please take following images as reference.

V-scoring has to be continuous and can not be stopped in panel, if you have many different boards like following image to be panelized, we suggest add tab routes between boards instead of V-scoring.

V-scoring is the most popular way in the PCB panel. V-scoring is the v-shape line to connect boards for convenience separation. We also require the v-scoring boards, please observe the following rules.

The gap between the individual circuit boards in the layout is 0mm based on the minimum spacing between copper pattern (trace/pad/copper ground) and V-cut line is 0.4mm.

Scoring lines must be straight; horizontal and vertical lines are possible, so the board's frame must be regular, and the size of boards must be over 75mm*75mm

For stability, we recommend using scoring only above a minimum circuit board thickness of 0.4mm

2. Tab route and stamp holes

For tab route and stamp holes, it can be used in the irregular boards. However, For the tab route, the space between boards should be 1.6mm.

Panel with Tab Route

For panel with tab routes, 1.6mm space is needed between boards. There are 2 kinds of tab routes be used for panel. One is tab route with breaking holes(stamp holes) and the other one is tab route with tab.(no holes).

Tab route with breaking holes (stamp holes)

For tab route with breaking holes diameter should be ≥0.45mm, regular diameter is 0.55mm-0.6mm. Holes space has to be ≥0.35mm, usually we will add 5-6 holes to each tab, please take following image as reference.

3. Breakaway rails

Breakaway rail, also called edge rail, is a rail at the edge of panel boards to fix the panel boards on a machine more easily. So it is usually used in assembly PCB boards.

For breakaway rails, you can also use a v-scoring or tab route to connect then you can cut the rails easily after assembly. In our factory, our mini edge rail is 5mm. Please see the following picture

Advantages

- Mass production. If you need to build a large number of PCBs, panelization will save you time and money.

- Product Safety. Panelization protects the PCB from shock and vibration during assembly.

- Speed and efficiency. From paste printing to component assembly, soldering, and even testing, as part of a large array, processing multiple boards at once is faster and more efficient.

Instructions and methods for panel FPC flexible circuit boards

In the production process of FPC flexible circuit board, in order to save cost, improve production efficiency, shorten the production cycle, often use the method of panel production, rather than single chip production.

Generally, FPC flexible circuit boards have three panel methods, namely, conventional panel, oblique panel and backward panel. All panel methods must follow the principle of material saving under the premise of production.

In FPC flexible PCB panel, you need to know those following principles:

- On the premise of each process can be produced, as far as possible ' squeeze '. The so-called ' extrusion ' is to reduce the distance between board and board, so as to reduce the size of the whole panel, save production materials and reduce production costs.

- The distance between the single plate is at least greater than 2mm, which is to meet the needs of placing positioning holes. In the process of mass production, the molding generally adopts the way of die-punching. In order to enhance the accuracy of die-punching, the positioning holes need to be placed between each piece in the panel to avoid the deviation of die -punching and lead to FPC scrap. In the process of sample production, laser cutting molding is generally used. In order to avoid slight deviation and prevent the occurrence of one deviation and the whole deviation, the chips cannot be directly connected, so that they do not affect each other.

- A panel need to add etching characters, the size of the plate, the number of simple instructions, so as to facilitate subsequent production check and calibration.

- The positioning hole is added in the four corners of the whole panel, and a corner is selected to mark different positioning holes, which is convenient for the subsequent production process to keep the direction consistent, so as not to cause the sealing film back, character printing and so on.

- The width of the panel is fixed to 250 mm, and the length is within 250 mm as far as possible. The larger the size of the panel, the greater the offset, the worse the production accuracy, and the higher the product failure rate.

Have Questions?

If you have any questions or need any further information, please feel free to contact your dedicated customer service.

Provide best in class solutions through engineering excellence and personalized service that exceeds our clients’ expectations.

Services

Get In Touch

Address:

17506 Murphy Parkway

Lathrop, CA 95330

U.S.A

Office: 833-722-3539

Email: Sales@AlteraFlex.com

SGS CN15/30057

SGS CN15/30242

SGS CN15/30241

© 2024 Content, including images, displayed on this website is protected by copyright laws. Downloading, republication, retransmission, or reproduction of the content on this website is strictly prohibited.

TERMS OF USE

|

PRIVACY POLICY

|

ACCESSIBILITY

| Website Built by

BROADPROXIMITY