Metal Core PCBs

Among all Metal core PCBs, Aluminum PCB is the most common type. The base material consists of an aluminum core and standard FR4. It features a thermal clad layer that dissipates heat in a highly efficient manner while cooling components and increasing the overall performance of the products. Currently, Aluminum Backed PCB is regarded as the solution to high power and tight tolerance applications.

MCPCB, Metal Core PCB, thermal PCB

Metal core pcb is abbreviated as MCPCB, it is made of thermal insulating layer, metal plate and metal copper foil, which has special magnetic conductivity, excellent heat dissipation, high mechanical strength and good processing performance. For metal core base material, there is aluminum and copper base materials.

Aluminum substrate is a kind of metal-based copper clad plate with good heat transferring and dissipation function. Copper substrate has better performance than aluminum, but its price is relatively more expensive than aluminum.

Clients order aluminum pcbs more often, because the price of aluminum pcb is much more economic, they are used for LED lighting, audio frequency apparatus and communication electronic equipment.

Single Layer MCPCB Structure

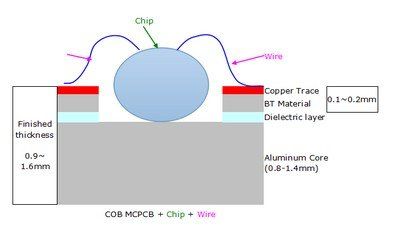

COB MCPCB, known as "Chip-On-Board" Metal Core PCB, is a type of MCPCB used in thermoelectric separation application.

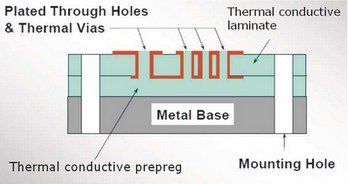

MCPCB Stack UP

A simple layer single sided MCPCB consists of a metal base (usually aluminum, or copper alloy), Dielectric (non-conducting) Layer, Copper Circuit Layer, IC components and solder mask.

Structure of COB MCPCB

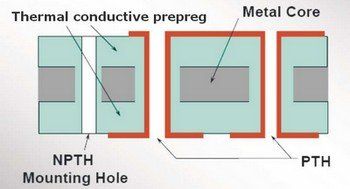

Two (Double) layers MCPCB is consisting of two layers of copper conductor, put them on same side of metal core (usually aluminum, copper or iron alloy).

Structure of 2L MCPCB

It also has same two layers of copper conductor like Double layers MCPCB, but the metal core is in the middle of two conductor, so there're conductors (trace) on both sides of metal core, and were connected to each other by Vias. So we named it "Double sided MCPCB", and you can populated SMD on both top and bottom.

Structure of Double Sided MCPCB

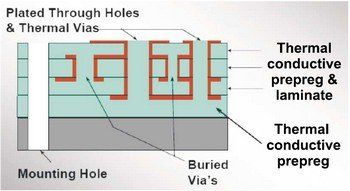

Multi Layers More Core PCB, you need to consult the salesperson first if AlteraFlex can be manufactured, The structure is similar with FR4 Multi Layers, but it much more complex to make.

Structure of Multi Layers MCPCB

Check below parameters about our aluminum pcb material.

According to the structure of metal core in the layers stack-up, AlteraFlex offers single side MCPCB, two layers MCPCB. For two layers MCPCB, which divides into metal core in the middle of layers stack-up, metal core on the bottom side of layers stack-up.

Have Questions?

If you have any questions or need any further information, please feel free to contact your dedicated customer service.