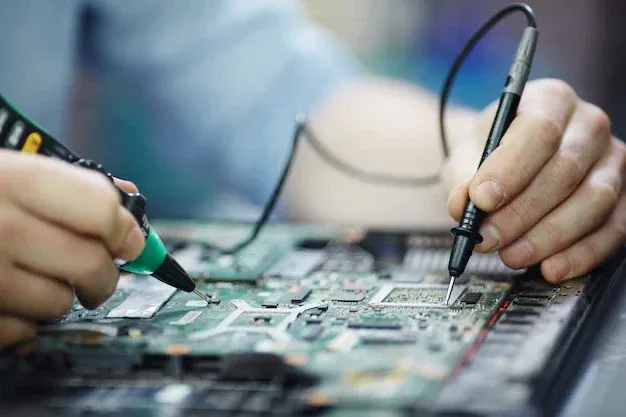

Through-Hole Assembly

Through-hole technology (also spelled "thru-hole"), refers to the mounting scheme used for electronic components that involve the use of leads on the components that are inserted into holes drilled in printed circuit boards (PCB) and soldered to pads on the opposite side either by the manual assembly (hand placement) or by the use of automated insertion mount machines.

Through-Hole Assembly

The quality of the solder joint is important for several reasons. The solder joint is the actual connection between the component and the board. The quality of the solder joint is equivalent to the quality of the connection. The "look" of the solder joint is less important but is usually indicative of the quality of the solder joint.

Characteristics:

While through-hole mounting provides strong mechanical bonds when compared to SMT techniques, the additional drilling required makes the boards more expensive to produce.

They also limit the available routing area for signal traces on layers immediately below the top layer on multilayer boards since the holes must pass through all layers to the opposite side.

To that end, through-hole mounting techniques are now usually reserved for bulkier or heavier components such as electrolytic capacitors or semiconductors in larger packages such as the TO-220 that require the additional mounting strength, or for components such as plug connectors or electromechanical relays that require great strength in support.

Have Questions?

If you have any questions or need any further information, please feel free to contact your dedicated customer service.